A Bill of Materials (BoM) is an effective way for manufacturers to organise the critical information that underpins production processes.

What exactly is a Bill of Materials? It’s essentially a list of the raw materials or components, quantities, time, and steps required to manage the production or assembly of finished goods.

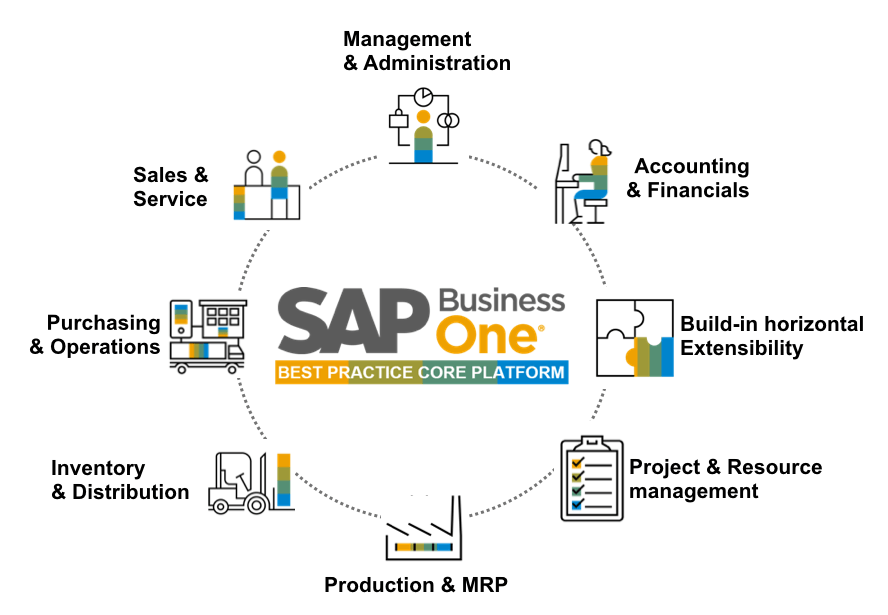

A BoM supports better planning, inventory management, costing and production efficiency—especially when they are created within a comprehensive Enterprise Resource Planning (ERP) solution.

SAP Business One is a leading ERP for small to mid-sized Australian manufacturers precisely because of its strong capabilities when it comes to planning production runs, including the management of BoMs, works orders and MRP

SAP Business One allows you to create three different types of BoMs:

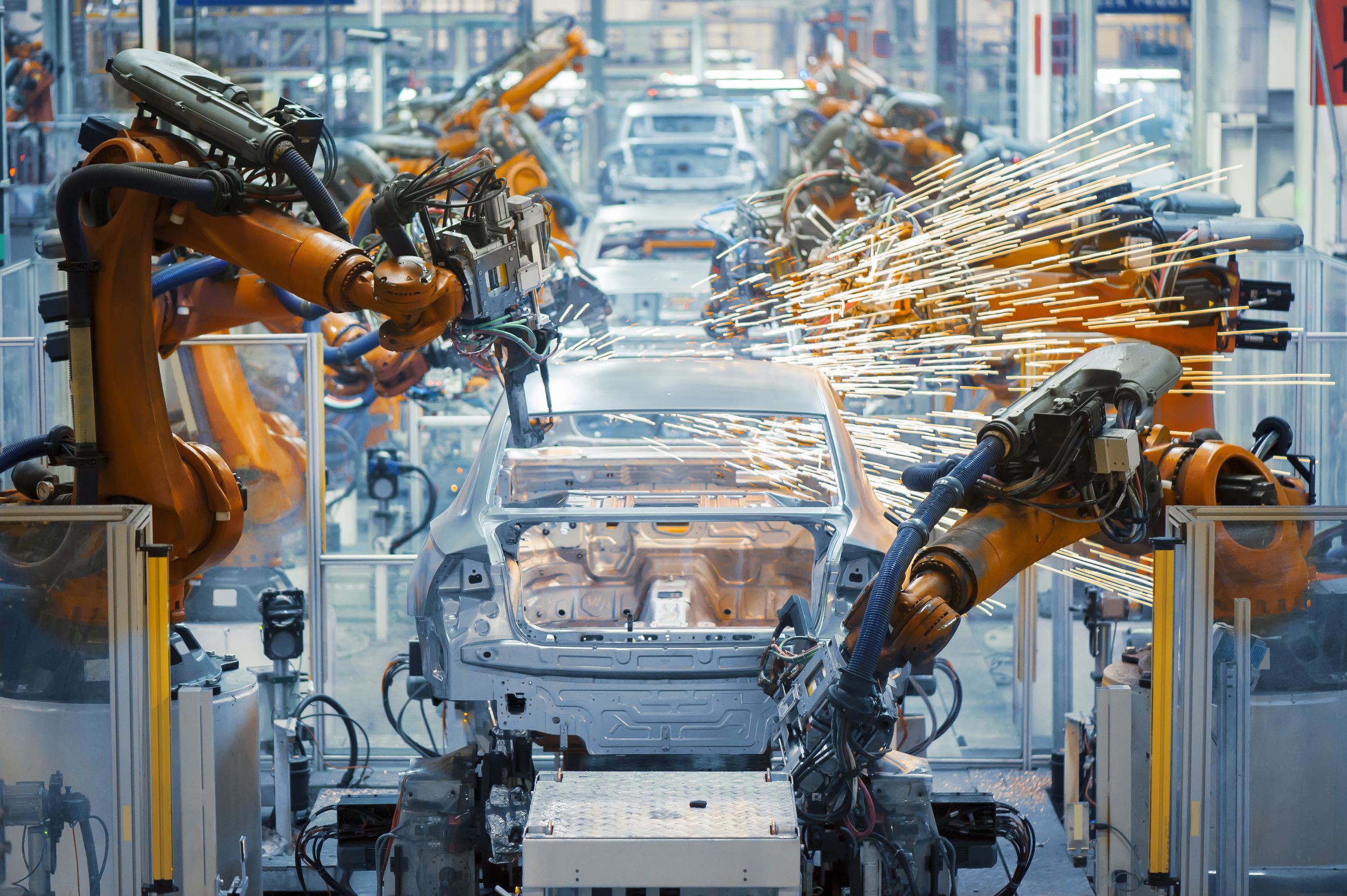

1.Production BoM:helps you to process a standard production order by turning various components or raw materials into a finished product by making use of machinery and labour.

2.Sales or Assembly BoM:allows you to group individual sales items in stock to sell a ‘parent’ product composed of multiple components which are then issued from the inventory once the order is dispatched. Both BoMs are for a fixed combination of items, but you’d use a Sales BoM if the customer needs confirmation of each component or wants to alter quantities.

3.Template BoM:Creates a list of items brought together for sale at the same time and gives you the flexibility to change the quantities, swap and delete items to customise a sales order.

Costings can be included in BoMs, which rolls up within the system to give you a clearer picture of how much products actually cost to make.

You can allocate a static cost for the set-up time of machines and a standard per minute/hour cost for run time. You can then split those costs across multiple GL accounts, perhaps if you wanted to recoup the cost of investing in a new machine via a different expense account.

It’s possible to globally maintain prices within BoMs using SAP Business One. Each component item has a price, which is often based on its cost price. The system can keep track of the last cost price and the moving average cost for an item.

Because BoMs in SAP Business One allows for precise costings, when you review your operation, you might decide the margin on production for some products is too low. It’s straightforward to implement price increases (e.g., a 10% increase) based on the criteria you enter and apply this to all relevant BoMs.

A production BoM is a useful ‘shopping list’ to guide manufacturing processes. Yet an accurate BoM is contingent on having clarity in other aspects of your operation such as understanding demand, lead times and stock availability.

When you select a production BoM in SAP Business One you can include the product in the Materials Requirement Planning (MRP) run, to gain high-level visibility of supply and demand, materials and capacity constraints.

The SAP Business One MRP wizard provides you with incredibly useful recommendations about how to juggle your stock, initiate production orders and generate purchase orders to meet future demand. That’s the beauty of an integrated, enterprise-wide solution that caters specifically to small and mid-sized manufacturers.

Whether your business involves discrete, process or assembly manufacturing, you need an ERP solution that handles Bill of Materials, works orders, MRP and kitting and contributes to better planning. SAP Business One makes it easy to manage materials, processes, and overall profitability.